I am just going to copy/paste this from my car forum over to here. I had it in our project logs forum there so it is vague and maybe a bit dumbed down for the car crowd that dont know boats or jet boats. So im not going to go through and edit it to make it a new post here. If you have any questions or advice let me know.

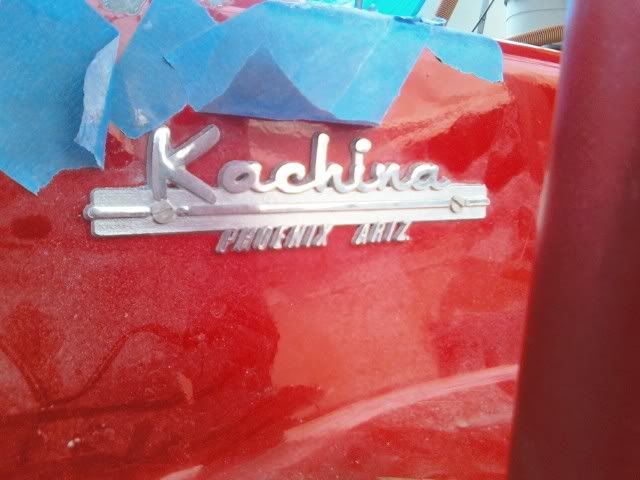

Ok so i bought this boat back in 2004 i think when living in TX. I drove out to AZ to pick it up. Thats another great story of its own. The boat is a 1978 made by Kachina boats whom is still in business still making custom boats. Although they make much larger boats now. Had a lot of fun in the boat until one of the fuel tanks started to leak due to the adding of ethanol to our fuel and fiberglass gas tanks. ******* regulations on fuel. After cutting out the tanks one thing lead to another and eventually i got the boat back to CA for some major work. So here was the boat basically when i bought it.

Leaking tanks.. coming through crack where tanks are tabbed in to hull. Means the actual tank is leaking and the fuel is making its way out of where they were glassed in. There are one tank on each side. Like 70 gallons of fuel +

flushing them heavily...

Ok so i bought this boat back in 2004 i think when living in TX. I drove out to AZ to pick it up. Thats another great story of its own. The boat is a 1978 made by Kachina boats whom is still in business still making custom boats. Although they make much larger boats now. Had a lot of fun in the boat until one of the fuel tanks started to leak due to the adding of ethanol to our fuel and fiberglass gas tanks. ******* regulations on fuel. After cutting out the tanks one thing lead to another and eventually i got the boat back to CA for some major work. So here was the boat basically when i bought it.

Leaking tanks.. coming through crack where tanks are tabbed in to hull. Means the actual tank is leaking and the fuel is making its way out of where they were glassed in. There are one tank on each side. Like 70 gallons of fuel +

flushing them heavily...