You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Commercial bender / Windshields

- Thread starter Crusader

- Start date

What would it take to have a splash guard built for a Liberator, or for any boat? What would you need to form, or bend the plastic. When you say a pattern, are you talking about a drawing or building the model out of some other material? I'm confused as to what is needed to produce the final product. Thanks, Jim think.gif

duanehydro

Active member

Crusader

Moderator

jdeaton said:OK, I can do that, but what happens next? Do you send that mockup to Cliff and he bends and molds the final product?

Hey bro. No, please don't send it to me......not yet anyway. Lol. I've never made a windshield or a splash guard before, my boat will be the first one I've done. I luckily stumbled upon a plexi bender (nothing more than a heater element wedged in a 2 inch channel) and am trying to make a windshield. Matt and Chad are going to make theirs too. If we get good at it, we might do a few here or there but right now we are just trying to get ours done and not screw someone else's up.

We can give you advice though.

Crusader

Moderator

All right...progress is being made on the Crusaders windshield. I ordered 20 feet of the 1/4 inch Edging for along the bottom of the windshield where it makes contact with the gel coat. I bought extra in case someone else needs to use it....the 20 feet cost about $54 worth of cheddar.

Here's the eBay link to the edging.

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=260652116154&ssPageName=STRK:MEWNX:IT

Once the windshield is cut and we get to forming it, I'll post pictures of the progress made.

Here's the eBay link to the edging.

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=260652116154&ssPageName=STRK:MEWNX:IT

Once the windshield is cut and we get to forming it, I'll post pictures of the progress made.

Crusader

Moderator

Devilman said:sweet, keep us updated. definitely wanna see your progress & the steps taken.. :smile17:

Will do Devilman! I'm putting on a Bimini top I got from Billy and will take pictures of that too. I love it when a plan comes together.

Crusader

Moderator

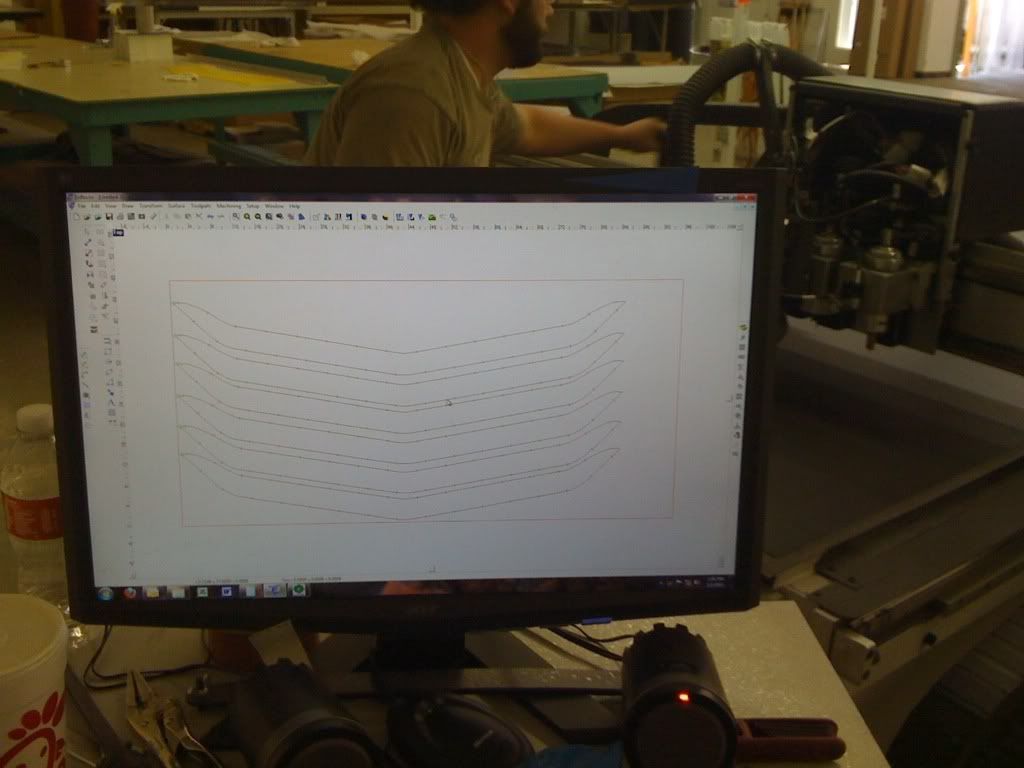

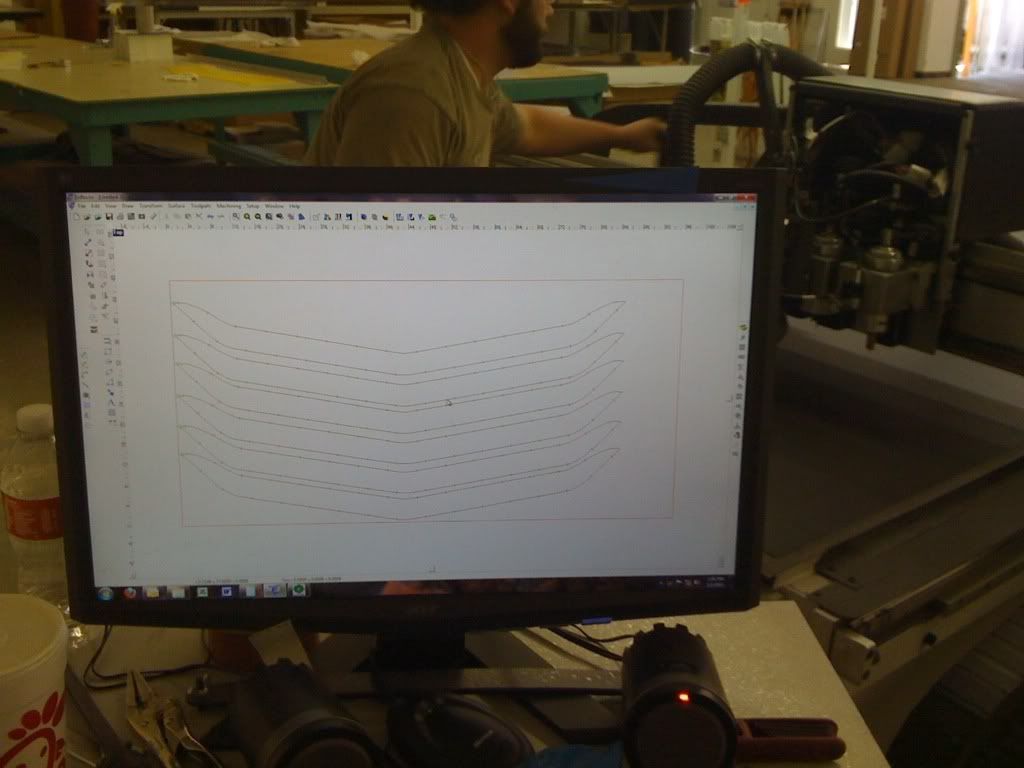

Progress is being made with the Crusaders windshield. Matt just sent me a few pictures of a template being cut on the CNC machine at the shop where he works. He made some templates first so I can bend them on the boat, align the holes where needed and then once I have that in place...... I have an exact idea and precise locations to bend and place hardware on the real windshield.

Here the windshield is computer drawn on the plastic

This is the plastic on the cutter just before the blade starts cutting the shape.

And this is the final plastic template material ready for me to put on the boat, and shape to fit.

Thanks a million Matt!!!!

Here the windshield is computer drawn on the plastic

This is the plastic on the cutter just before the blade starts cutting the shape.

And this is the final plastic template material ready for me to put on the boat, and shape to fit.

Thanks a million Matt!!!!

Last Mohecian

Administrator

We cut those templates out of styrene on a digital knife. They are quite thin and just to check measurements. The final product will be cut out of 1/4" acrylic on a digital router table.

Crusader

Moderator

The original windshield was forward leaning. I'm more into a sleek look so we created a cardboard template witht he windshield leaning back....so that is what Matt and I created using a pencil, cardboard, blue tape and the 'ole Mark 1 eyeball.

Matt will have to talk about how the image went into the computer...it's all FM (Freakin' Magic) to me. lol.

Matt will have to talk about how the image went into the computer...it's all FM (Freakin' Magic) to me. lol.

Last Mohecian

Administrator

Black box magic trade secret. LOL.

Last Mohecian

Administrator

Devilman said:Thats pretty damn cool, thanks for the update pics. clap.gif

I probably missed it, but is this going to be a forward leaning windshield or a swept back?

How did you go about getting those drawings for the computer.

Cliff and I hand made a template with thin styrene. One side of that template was scanned in segments with a flat bed scanner into Illustrator. The segments were pieced back together and the lines were straightened out in illustrator. That side was flipped and joined in illustrator to create a perfectly symmetrical template. The template was plotted with a pin on paper and compared to the original template Cliff and I made. Once we confirmed it was close and clean we cut the new symmetrical template out with the digital knife for Cliff to take back to the boat and make sure it fits correctly. Once Cliff confirms the template is correct we will cut the final product.

Just FYI, this is a one time project. I need a windshield for my cruiser and I am fortunate enough to have a client that has the technology and a little free time right now. I can get 3 or 4 windshields out of a 4X8 sheet of material so cutting 1 or cutting 4 was no different to me. This is not something I could do on a regular basis.

I'll try to video the router table cutting the final product when we get to that stage.

Matt