ChryslerJet

New member

Okay so I am moving my project from the newbies section to here bit by bit will see how that goes. This is going to be duplicating some of those posts just so they are all together here will be removing them from that thread once they are all reposted here.

Here in follows the story of the boat and the progress of the tear down and rebuild.

This is a badly abused and abandoned boat I found on Craigslist for $400 listed as a Mopar being sold by a Mopar enthusiast like myself in Bulverde Tx. There wasn't ever going to be another buyer out there for this boat. He had rescued it from going to the junk yard from the previous owner thinking he would fix it up but he was never a boat person and never got around to it. So basically since 1985 this boat has been sitting in one field or another in the Texas heat.

Now for a little history lesson most people don't know that Chrysler made boats but they bought out Lonestar boat in Plano Texas and started making their own line of boats which lasted until early 80's when Chrysler got into trouble and the govt made them drop all lines that were not dealing with the automotive industry. The boats made from the 60's through the 80's were manufactured under Chrysler Boat Corporation.

This boat is unique in that it not only is a boat made by Chrysler powered by a Chrysler Inboard motor it also has a Jet drive designed and manufactured by Chrysler as an all new Jet Drive. The Jet Drive as stated before had a very short run.

Here are a couple of pics from the Craigslist ad that I saw when I bought it and it looked pretty much the same when I picked it up to bring it home.

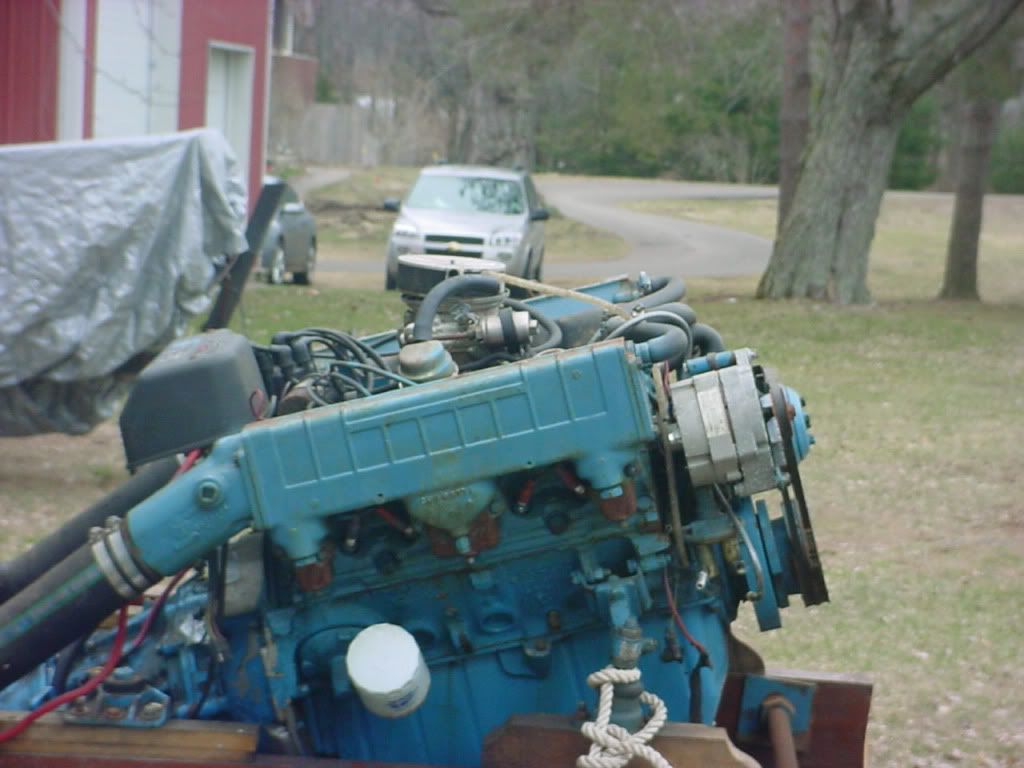

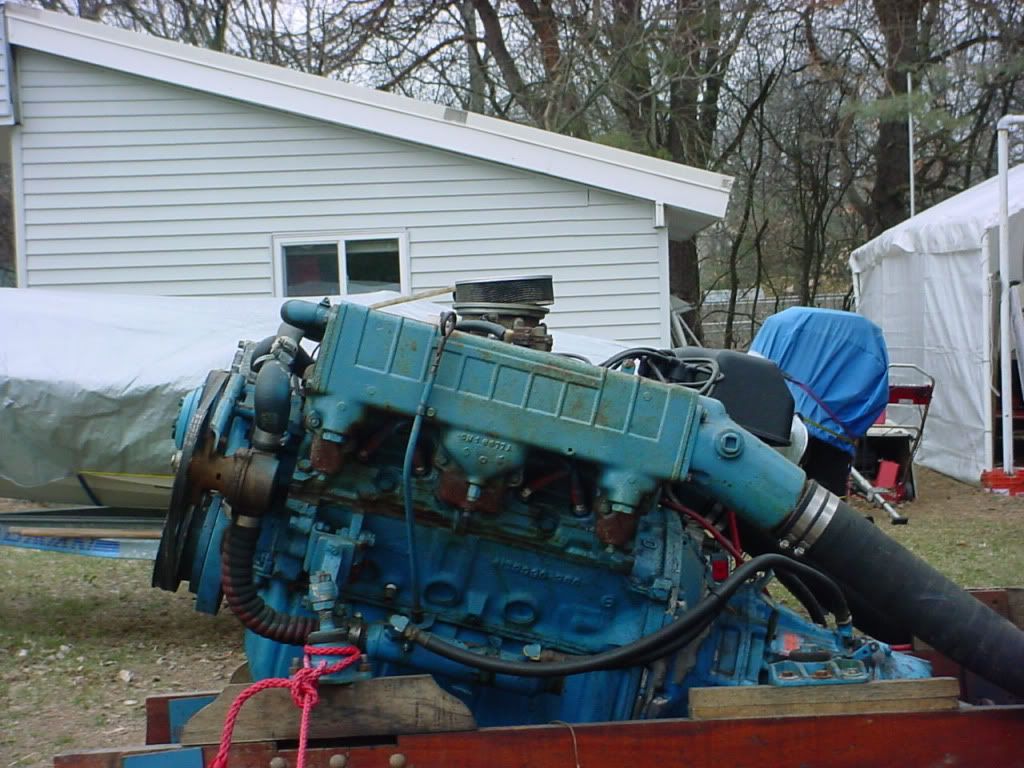

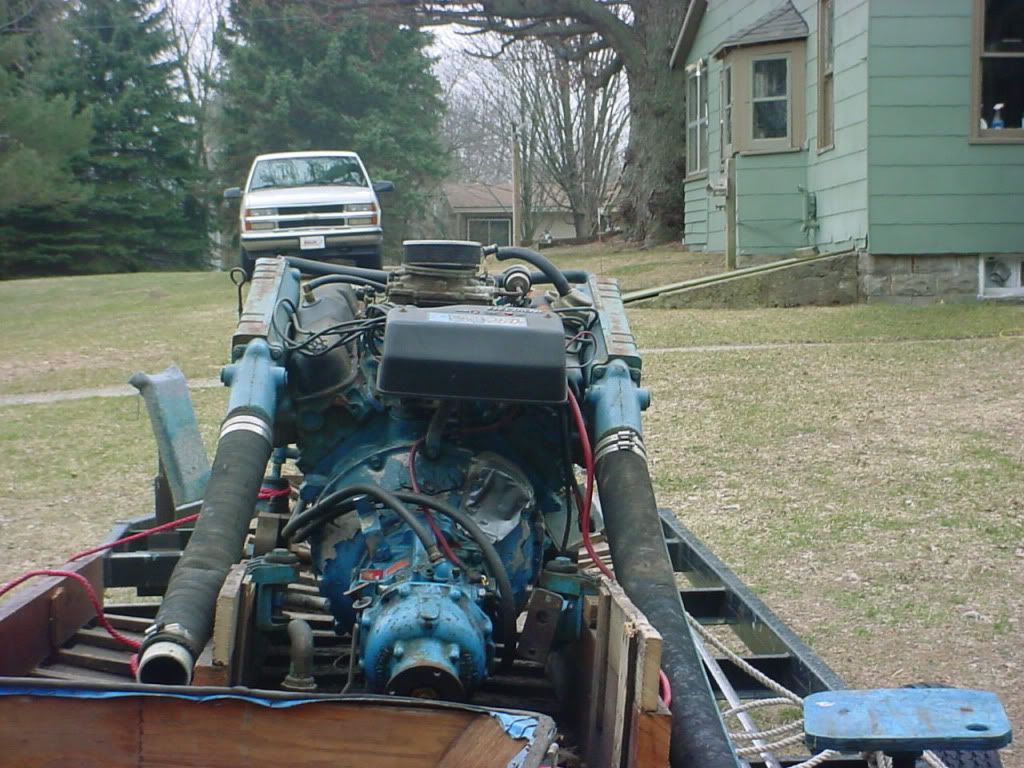

Well when I went to see the boat it was up on a hill. I got in carefully fully expecting to fall through the rotted wood. The floor was soft but not going to falter. The motor was long gone so no 340 it will be getting a 360 pics on that later. BTW I know how everyone loves pics I have lots of them and will post them all. The captains chair was there but that was it as far as the interior goes. The jet appeared to be complete and the direct drive to it was there along with the flywheel, bellhousing, and exhaust manifolds. There was also a raw water pump that was in bad shape but rebuildable. All the other accessories were missing (alternator, spark arrestor, starter, carb, brackets, motor mounts, etc.).

Well I told the guy I would get back with him and a month later the boat was still there (like I said it wasn't going to anyone else) I offered him $250 for it and I think I might have overpaid. The Tires were held on by bolts and nuts not lugs and studs, the hitch was also not positively locking wrapped some bailing wire around it to keep it from coming off, and to top it all off I had a 30 mile drive home half way home one of crossmembers, the second one back from the front, the welds broke and it dropped and was dragging underneath the trailer being held on by one rusty bolt to the end of a piece of rotted 2x4 bunk board. My luck was with me and whoever was driving behind me cause I could just see that thing bouncing down the road behind me into someones windshield. Of all the things that could happen that was the last thing I would have thought that would have happened. It made the rest of the trip home safely though.

Next post though will post some more pics of the boat and then some of the initial issues found.

BTW this all Happened Jan 2011, my goal was to have it water ready by April 25th 2011 my birthday. It may not have been pretty but would have been on the water for the first time in 26 years. That didn't happen partly because I hadn't realized how hard it was going to be to get a motor and all the accessories for this thing, particularly the CCW Starter.

Thanks for reading

Here in follows the story of the boat and the progress of the tear down and rebuild.

This is a badly abused and abandoned boat I found on Craigslist for $400 listed as a Mopar being sold by a Mopar enthusiast like myself in Bulverde Tx. There wasn't ever going to be another buyer out there for this boat. He had rescued it from going to the junk yard from the previous owner thinking he would fix it up but he was never a boat person and never got around to it. So basically since 1985 this boat has been sitting in one field or another in the Texas heat.

Now for a little history lesson most people don't know that Chrysler made boats but they bought out Lonestar boat in Plano Texas and started making their own line of boats which lasted until early 80's when Chrysler got into trouble and the govt made them drop all lines that were not dealing with the automotive industry. The boats made from the 60's through the 80's were manufactured under Chrysler Boat Corporation.

This boat is unique in that it not only is a boat made by Chrysler powered by a Chrysler Inboard motor it also has a Jet drive designed and manufactured by Chrysler as an all new Jet Drive. The Jet Drive as stated before had a very short run.

Here are a couple of pics from the Craigslist ad that I saw when I bought it and it looked pretty much the same when I picked it up to bring it home.

Well when I went to see the boat it was up on a hill. I got in carefully fully expecting to fall through the rotted wood. The floor was soft but not going to falter. The motor was long gone so no 340 it will be getting a 360 pics on that later. BTW I know how everyone loves pics I have lots of them and will post them all. The captains chair was there but that was it as far as the interior goes. The jet appeared to be complete and the direct drive to it was there along with the flywheel, bellhousing, and exhaust manifolds. There was also a raw water pump that was in bad shape but rebuildable. All the other accessories were missing (alternator, spark arrestor, starter, carb, brackets, motor mounts, etc.).

Well I told the guy I would get back with him and a month later the boat was still there (like I said it wasn't going to anyone else) I offered him $250 for it and I think I might have overpaid. The Tires were held on by bolts and nuts not lugs and studs, the hitch was also not positively locking wrapped some bailing wire around it to keep it from coming off, and to top it all off I had a 30 mile drive home half way home one of crossmembers, the second one back from the front, the welds broke and it dropped and was dragging underneath the trailer being held on by one rusty bolt to the end of a piece of rotted 2x4 bunk board. My luck was with me and whoever was driving behind me cause I could just see that thing bouncing down the road behind me into someones windshield. Of all the things that could happen that was the last thing I would have thought that would have happened. It made the rest of the trip home safely though.

Next post though will post some more pics of the boat and then some of the initial issues found.

BTW this all Happened Jan 2011, my goal was to have it water ready by April 25th 2011 my birthday. It may not have been pretty but would have been on the water for the first time in 26 years. That didn't happen partly because I hadn't realized how hard it was going to be to get a motor and all the accessories for this thing, particularly the CCW Starter.

Thanks for reading